With modern day engines try and obtain live data when cranking, things to check are,

Low Fuel Pressure

Modern fuel injection systems are all about pressure and volume of fuel. Many running problems could either be inadequate fuel supply to the high-pressure pump/rail/injectors or the rail/injectors are not holding the fuel within the system. The best way to diagnose this is as follows:

- Check that it is diesel in the tank and not petrol/contaminated fuel, also the level of fuel.

- Does the tank have an internal electric feed pump, or is there an in-line supply pump?. Feed pressures from the tank to the filter can vary from .20 to 5.0 bar. Find out what yours should be and CHECK IT with a pressure gauge. Don’t just do a visual check as this does catch many mechanics out.

- From the tank, the fuel goes through to the fuel filter, replace it with a GENUINE unit and make sure that the filter housing looks good.

- Look at all plastic/rubber fuel supply pipes and connections to and from the filter; they must be dry, there must be no signs of wetness. If they are damp, replace them.

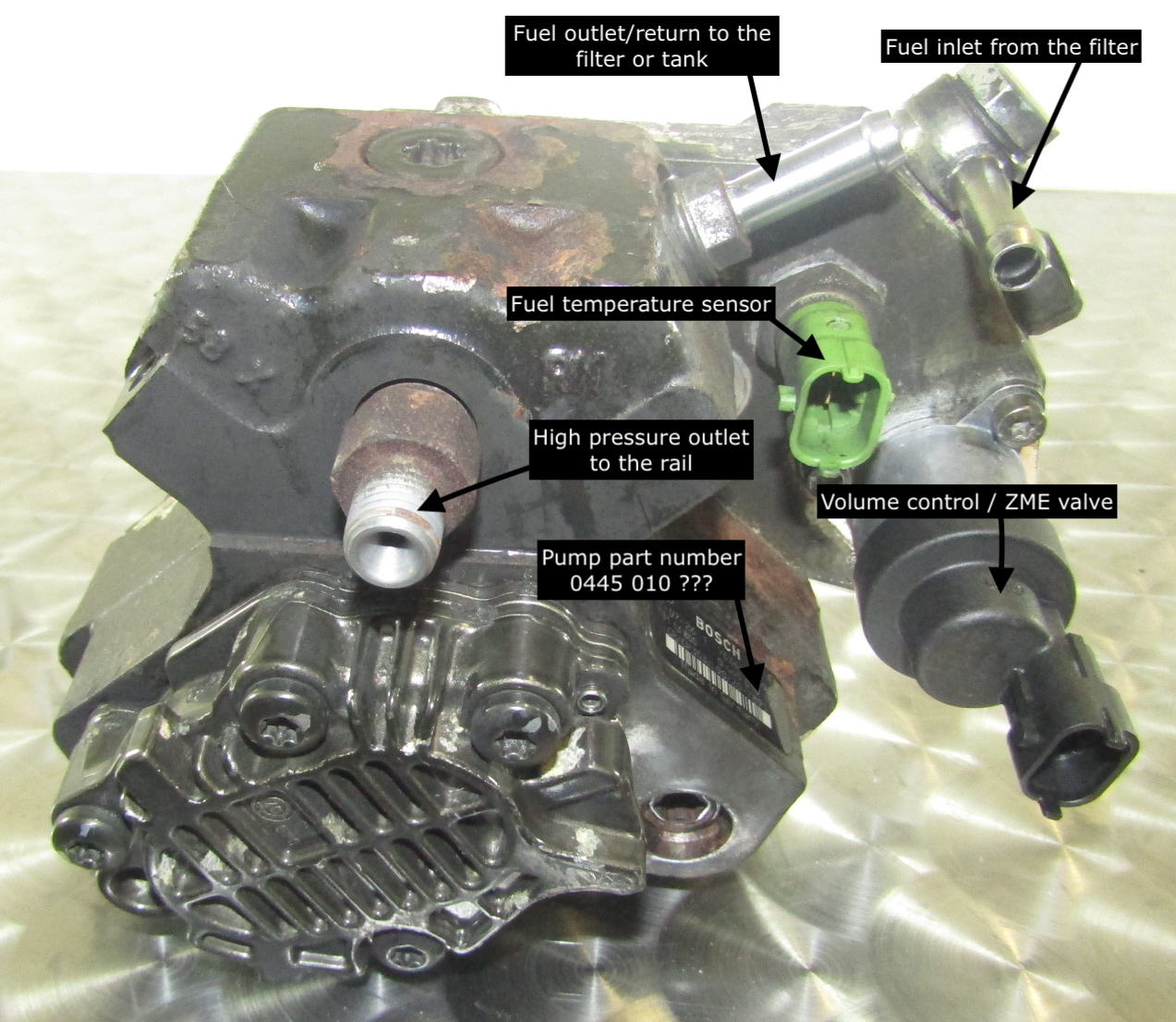

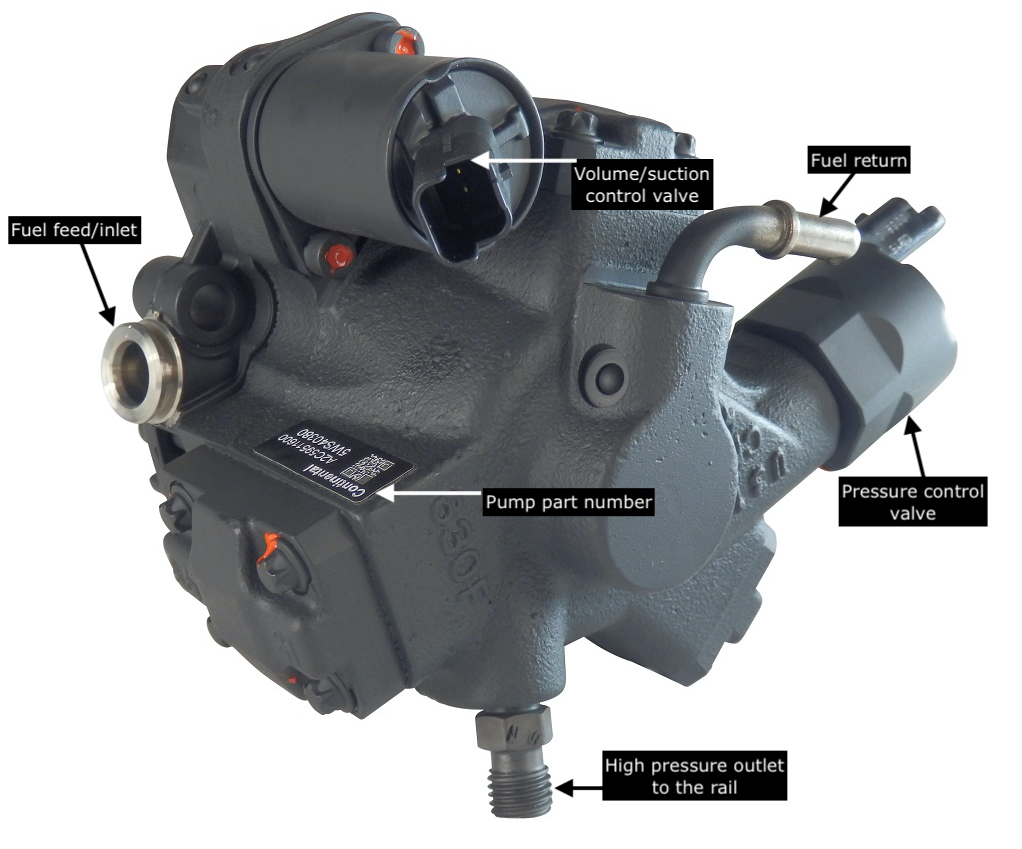

- The High-pressure pump will probably have one to three electrical valves/sensors on it. Check that the electrical connections are all tight and look good. If you can remove the steel pipe from the pump to the rail, do this and check the fuel pressure exiting the pump, at cranking you should get between 200 and 300 bar. Remove the electrical plug on the volume /suction control valve and see if the pressure increases. Some pumps go into maximum supply pressure by disconnecting the electrical supply to the valve.

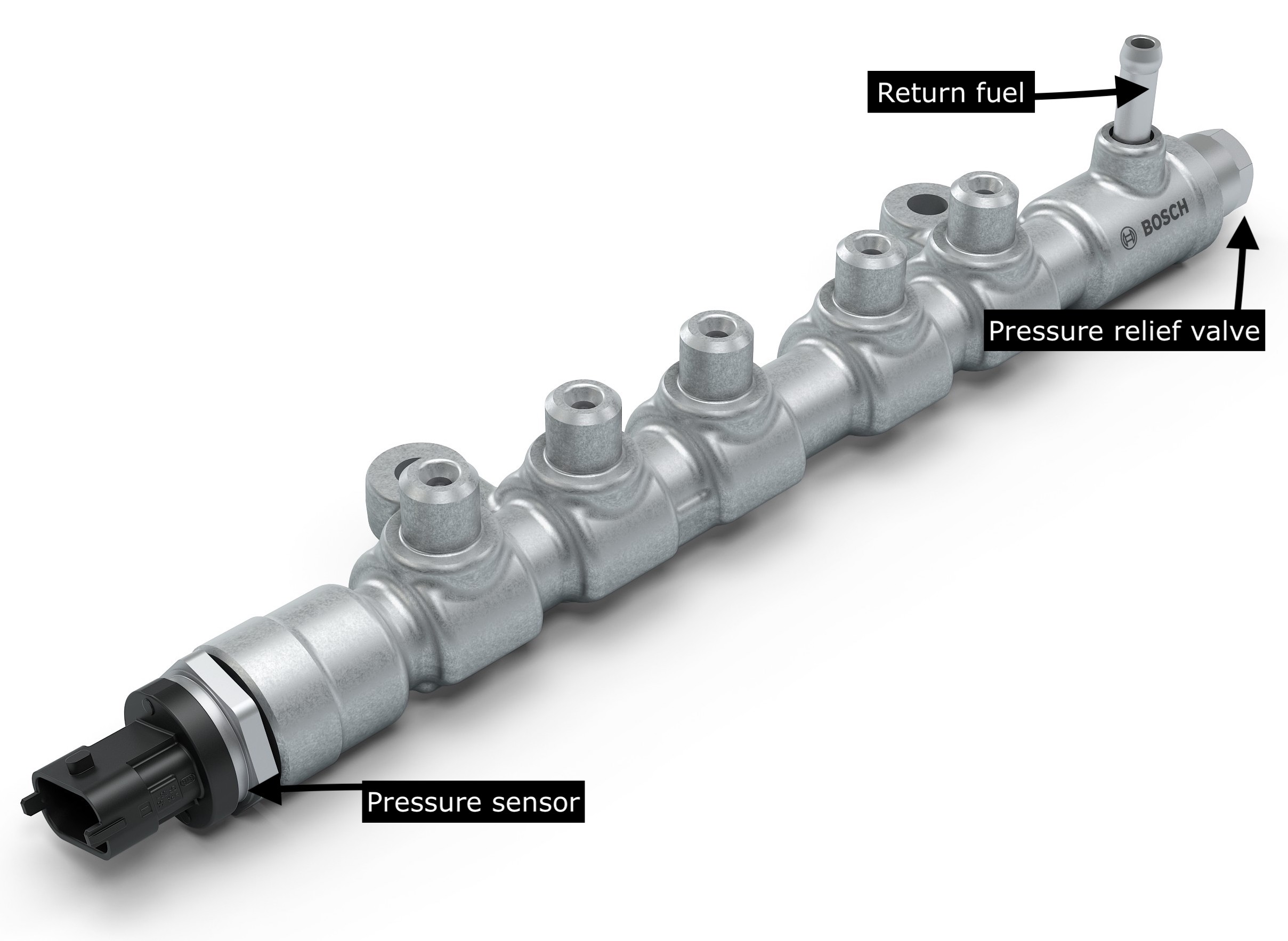

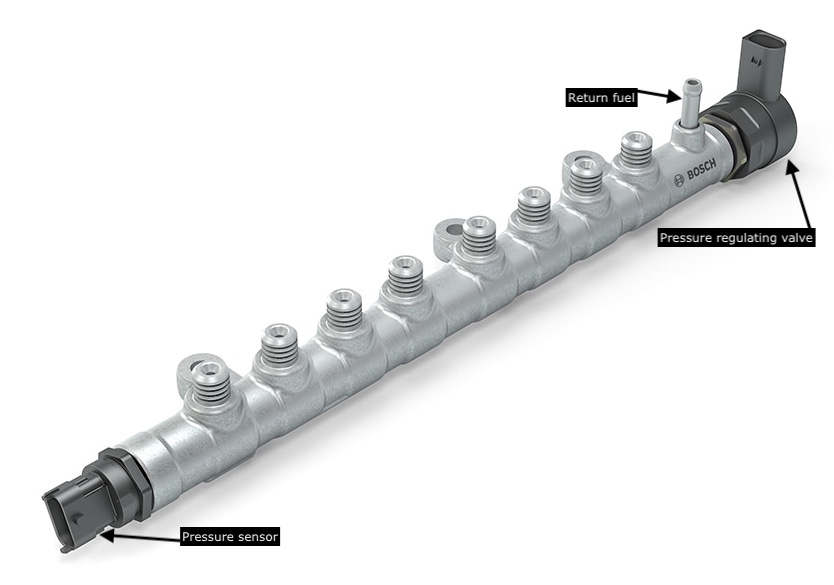

- The next thing to check is the rail; they differ so check what you have on yours. Some have a pressure sensor, a relief valve and possibly a pressure regulating valve. The sensor tells the ECU what the pressure is in the rail. The relief valve returns fuel if the pressure gets too high in the rail and the regulating valve regulates the pressure in the rail.

- The last area for a pressure loss is the injectors. Two things can cause a problem, either a nozzle is stuck open, and fuel is pouring into the cylinder, or the injectors are faulty allowing for fuel to pass through the injector and return to the filter or tank. This is normally called a back-leakage test.

Low Engine Compression

Low engine compression will result in insufficient heat being generated to ignite the fuel and cause hard starting. This is more of a problem with older or high mileage vehicles. To find out the compression perform a cold engine compression test. Compression should be between 20 to 35 bars or 300 to 500 PSI. Anything below this will cause starting problems.

Low Cranking Speed – Flat Battery

If the engine turns over too slowly, the pump cannot generate enough fuel pressure to activate start of injection causing hard starting problems. This is usually seen more in the colder months especially if the battery is run down.

Glow Plugs or Relay Faulty

The engine relies on the glow plugs to generate heat to help with the combustion cycle. Some engines only use the glow plugs when cold but others will allow the glow plugs to work when the ECU (vehicle’s computer) needs them to be on to help with combustion. Problems in this area will cause diesel engine starting problems, uneven running and white smoke when the engine is cold.

Insufficient Fuel Supply

This speaks for itself, not enough fuel in the tank or a problem with supply pipes being cracked or bent. The fuel tank breather can sometimes be blocked causing a vacuum in the tank which in turn draws the fuel back to the tank.

Fuel Quality and Contamination

Poor or contaminated fuel will reduce the life of your diesel injection equipment. Water robs the fuel of its lubrisity which will cause premature wear. Transfering fuel from drums also results in contaminated fuel, we are also seeing failures due to Adblue being put into the diesel.

Air – Vacuum in Fuel Supply

This is similar to “Insufficient fuel supply” (above) but dirty fuel filters or a faulty filter head assembly may also cause fuel supply issues and hard starting.

Blocked Fuel Supply or Dirty Fuel Filters

First thing to do when fault finding is to replace the fuel filter with and O.E. one. Also make sure that there are no blockages in the fuel supply lines.

Faulty Diesel Injector(s)

Probably the biggest result of injector failure is due to the injectors having excessive return flow or back leakage. This is due to worn parts which allow excessive fuel to go through the diesel injector and to return back to the tank or fuel system. This causes a drop in rail pressure (see “Low fuel pressure”) which results in hard starting or not starting at all.

Another problem resulting from worn parts is a delay in the start of injection which in turn results in rough running at low RPM or your diesel not starting.

We are also seeing problems with the later Bosch Piezo injectors that are causing white smoke at idle. The vehicle builds up excessive white smoke at idle but then tends to clear onacceleration. We have found that the nozzles dribble resulting in unburnt fuel.

For peace of mind send your injectors in for testing, ask us for a quote.

Faulty High Pressure Pump

If the pump is faulty there will be a “Low fuel pressure” problem. This problem arises if the pump “breaks up” internally causing swarf and iron filings to get into the fuel system. Normally this causes damage to the diesel injectors and unless the complete fuel system is attended to the problem will arise again. This is an expensive failure and no short cuts can be taken.

Faulty Pressure Regulator or Sensor

Most vehicles have a pressure regulator fitted on the high pressure pump and a sensor fitted on the rail. If either of these are faulty there will be running issues like hard starting, uneven tick over and the vehicle cutting out when the RPM is increased.

Faulty Low Pressure Supply Pump

Not all vehicles have a low pressure supply pump but if they do it can be found either in the tank or on the fuel pipe near the tank. If your low pressure pump is faulty, you may experience symptoms similar to those of a “Faulty high pressure pump”.

Cam and Crank Sensors

Check that the sensors are not loose, cracked or damaged as they are not very expensive. If you have any doubts I would recommend replacing them.

Electrical Wiring Harness

As vehicles age the wiring harnesses become brittle and wires break causing very difficult faults to find. Check continuity and resistance on all supply wires.